Hastelloy C22 vs Hastelloy C276: Which Alloy is Best for Corrosive Environments?

At 2 a.m., a chemical plant engineer receives a call no one wants—unexpected corrosion has compromised a critical component in a reactor line. The alloy chosen years ago was considered industry standard, yet today it is failing under aggressive chlorides and oxidizing acids.

In industries like chemical processing, pharmaceuticals, pollution control, oil & gas, and marine systems, choosing between Hastelloy C22 and Hastelloy C276 is not theoretical. The decision directly impacts equipment life, safety, and operational reliability.

Understanding Hastelloy Alloys in Corrosive Applications

Hastelloy is a family of nickel-based superalloys engineered to withstand extreme corrosion, high temperatures, and mechanical stress. Among them, C22 and C276 are two of the most widely specified grades for corrosive environments.

While both alloys deliver exceptional performance, they are optimized for slightly different corrosion challenges. Understanding these differences is essential before selecting Hastelloy wire mesh, fasteners, or fabricated components.

Chemical Composition: Where the Differences Begin

Hastelloy C276 – Typical Chemical Composition

- Nickel (Ni): ~57%

- Chromium (Cr): 14.5–16.5%

- Molybdenum (Mo): 15–17%

- Iron (Fe): 4–7%

- Tungsten (W): 3–4.5%

Hastelloy C22 – Typical Chemical Composition

- Nickel (Ni): ~56%

- Chromium (Cr): 20–22.5%

- Molybdenum (Mo): 12.5–14.5%

- Iron (Fe): 2–6%

- Tungsten (W): 2.5–3.5%

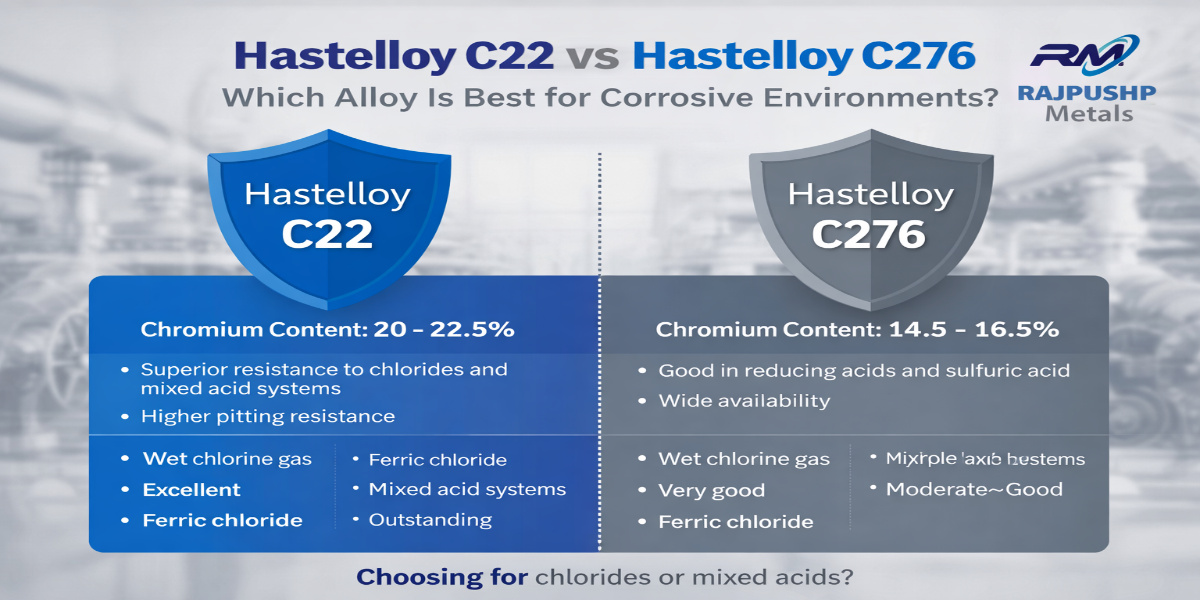

Key takeaway: The higher chromium content in Hastelloy C22 significantly improves resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in mixed oxidizing and reducing environments.

Corrosion Resistance: Real-World Performance Comparison

| Environment | Hastelloy C276 | Hastelloy C22 |

|---|---|---|

| Wet chlorine gas | Very good | Excellent |

| Ferric chloride | Good | Superior |

| Sulfuric acid | Excellent | Excellent |

| Mixed acid systems | Moderate to good | Outstanding |

| Seawater exposure | Good | Better long-term resistance |

For applications such as Hastelloy C22 fasteners or filtration-grade Hastelloy wire mesh, localized corrosion resistance is often more critical than uniform corrosion resistance.

Fabrication and Availability Considerations

Hastelloy C276

- Widely available across global markets

- Decades-long proven performance

- Commonly specified in legacy systems

Hastelloy C22

- Slightly higher material cost (approximately 10–20%)

- Optimized for modern aggressive chemistries

- Lower long-term maintenance and replacement risk

Lifecycle cost studies show that higher pitting resistance alloys can reduce unplanned replacement costs by up to 40% over long operating periods.

Which Alloy Should You Choose?

Choose Hastelloy C276 if:

- Your system primarily faces reducing acids

- You are replacing existing C276 components

- Cost sensitivity outweighs corrosion variability

Choose Hastelloy C22 if:

- Your process involves chlorides and oxidizing agents

- You have experienced pitting or crevice corrosion failures

- You need higher reliability in compact components

Common Buyer Questions

- Will Hastelloy C22 outperform C276 in my chemical environment?

- Is Hastelloy wire mesh available with certified test reports?

- How does weldability compare between C22 and C276?

- Are Hastelloy C22 fasteners suitable for pressure vessels?

- Which ASTM and ASME standards apply?

How Rajpushp Metals Supports Technical Buyers

Rajpushp Metals works closely with engineers and procurement teams to supply verified Hastelloy C22 and C276 materials with full documentation, dimensional accuracy, and application guidance. This ensures material selection is based on real operating conditions rather than assumptions.

Conclusion

Both Hastelloy C22 and Hastelloy C276 are exceptional corrosion-resistant alloys. The right choice depends on your chemical environment, risk tolerance, and lifecycle expectations. Selecting the correct alloy from the start can prevent costly downtime, safety risks, and premature failures.